Bare AAAC Conductor

Tags : AAAC,Aluminum Alloy Conductor,AAAC bare conductor

Summary: The all aluminum alloy conductor is one of the most common bare conductors in our life and industry production. T is usually short as and to be used for bare overhead transmission cable and as primary and secondary distribution cable

Description

All Aluminum Alloy Conductor APPLICATION

AAAC is mainly used as bare overhead transmission cable and as primary and secondary distribution cable. It is also suitable for laying across basins, rivers and valleys where special geographical teatures exist.

STANDARD

All Aluminum Alloy Conductor are basic design to BS 3242 / BS EN 50182 / IEC 61089 / ASTM B 399/B 399M / DIN 48201-6 standards.

All Aluminum Alloy Conductor

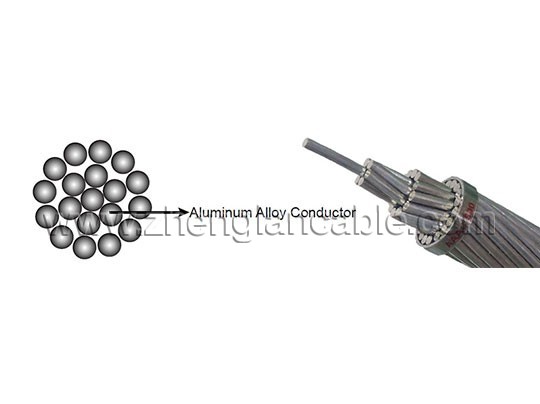

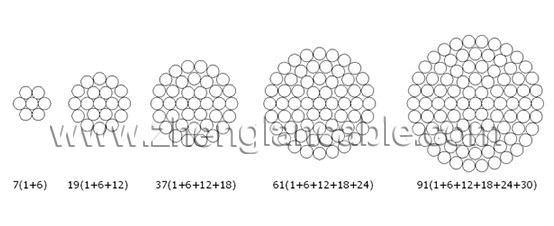

AAAC cable bvconsists of aluminum alloy wires. The aluminum alloy wires are concentrically stranded.

This section deals with heat-treatable magnesium silicon type aluminium alloys to the applicable International Standard, the electrical and mechanical properties of which all fall within the values suggested by relevant standard. Conductors to all other recognized specifications can also be supplied. The alloys referred to have higher strength but lower conductivity than pure aluminium. Being lighter, alloy conductors can sometimes be used to advantage in place of the more conventional ACSR; Having lower breaking loads than the later, their use becomes particularly favourable when ice and wind loadings are low

Specifications

ELECTRICAL PROPERTIES

|

Density@20°C |

2.70 kg/dm |

|

Temperature Coefficient@20°C |

0.00360 (°C) |

|

Resistivity@20°C |

0.0326 Ohms mm²/m |

|

Linear Expansivity |

23 x10 -6 (°C) |

SERVICE CONDITIONS

|

Ambient Temperature |

-5°C - 50°C |

|

Wind Pressure |

80 – 130kg/m² |

|

Seismic Acceleration |

0.12 - 0.05g |

|

Isokeraunic level |

10 – 18 |

|

Relative Humidity |

5 – 100% |

All Aluminum Alloy Conductor CONSTRUCTION PARAMETERS ASTM B399/B399M

|

Nominal Area |

Stranding |

Overall |

Weight |

Rated |

Electrical |

Current |

|

|

AWG&MCM |

mm² |

No.x mm |

mm |

Kg/Km |

KN |

Ω/Km |

A |

|

6 |

13.2 |

7/1.55 |

4.65 |

36.2 |

4.18 |

2.5361 |

69 |

|

4 |

21.1 |

7/1.96 |

5.88 |

57.9 |

6.69 |

1.586 |

93 |

|

2 |

33.5 |

7/2.47 |

7.41 |

92 |

10.6 |

0.9987 |

123 |

|

0 |

53.5 |

7/3.12 |

9.36 |

146.8 |

17 |

0.62592 |

165 |

|

2/0 |

67.3 |

7/3.50 |

10.5 |

184.8 |

20.4 |

0.49738 |

190 |

|

3/0 |

84.9 |

7/3.93 |

11.79 |

233 |

25.7 |

0.3945 |

219 |

|

4/0 |

107 |

7/4.42 |

13.26 |

294.7 |

32.5 |

0.31188 |

253 |

|

250 |

126 |

19/2.91 |

14.55 |

346.7 |

38.8 |

0.26509 |

280 |

|

500 |

253 |

19/4.12 |

20.6 |

695 |

74.2 |

0.13224 |

429 |

|

550 |

279 |

37/3.10 |

21.7 |

766.2 |

83.9 |

0.11995 |

455 |

|

1000 |

508 |

37/4.18 |

29.26 |

1393 |

146 |

0.06597 |

653 |

|

1250 |

631 |

61/3.63 |

32.67 |

1732 |

179 |

0.05306 |

743 |

All Aluminum Alloy Conductor CONSTRUCTION PARAMETERSASTm BS EN 50182

|

Code |

Stranding |

Nominal Area |

Overall |

Weight |

Rated |

Electrical |

Current |

|

|

No.x mm |

mm² |

mm |

Kg/Km |

KN |

Ω/Km |

A |

|

Box |

7/1.85 |

18.8 |

5.55 |

51.4 |

5.55 |

1.748 |

87 |

|

Acacia |

7/2.08 |

23.8 |

6.24 |

64.9 |

7.02 |

1.3828 |

101 |

|

Almond |

7/2.34 |

30.1 |

7.02 |

82.2 |

8.88 |

1.0926 |

116 |

|

Cedar |

7/2.54 |

35.5 |

7.62 |

96.8 |

10.46 |

0.9273 |

129 |

|

Holly |

7/3.91 |

84.1 |

11.73 |

229.5 |

24.79 |

0.3913 |

219 |

|

Oak |

7/4.65 |

118.9 |

13.95 |

324.5 |

35.07 |

0.2767 |

272 |

|

Mulberry |

19/3.18 |

150.9 |

15.9 |

414.3 |

44.52 |

0.2192 |

314 |

|

Elm |

19/3.76 |

211 |

18.8 |

579.2 |

62.24 |

0.1568 |

386 |

|

Poplar |

37/2.87 |

239.4 |

20.09 |

659.4 |

70.61 |

0.1387 |

416 |

|

Totara |

37/4.14 |

498.1 |

28.98 |

1372.1 |

146.93 |

0.0666 |

648 |

|

Rubus |

61/3.50 |

586.9 |

31.5 |

1622 |

173.13 |

0.0567 |

714 |

|

Sorbus |

61/3.71 |

659.4 |

33.39 |

1822.5 |

194.53 |

0.0505 |

764 |

Related Products

Copper Wire Braid Shielded Control Cable

Tags :Control cables,PVC Insulated and sheathed cable,braid shielded control cable

Inquiry

Bare Stranded Copper Conductor

Tags :Copper Conductor,Bare Copper conductor,Stranded Bare Copper

Inquiry

Computer Cable

Tags :Computer cable with copper screen,XLPE Inslatd Control cable, Instrument PVC Jacke Cable

Inquiry

Flexible Mineral Insulated Isolation Type Fire Resistant Cab...

Tags :Fire Resistant Cable,Mineral Insulated Cable,FRC

Inquiry

Copper Metallic Sheathed Fire Resistant Cable (YTTW)

Tags :Fire Resistant Cable,YTTW,Copper Metallic Sheathed Fire Resistant Cable

Inquiry

Flexible Mineral Insulated Fire Resistant Cable (BBTRZ)

Tags :Mineral insulated cables,Fire Resistant Copper cable,BBTRZ

Inquiry

GET IN TOUCH

If you have any questions, please fill in the following information and we will respond to you in time.